Small Digging Machines: From Modest Beginnings to Astounding Tech

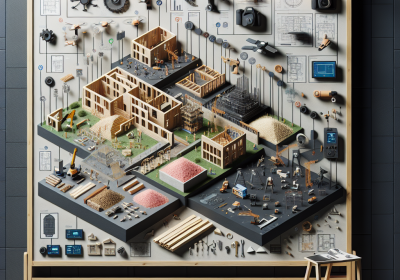

In construction’s constantly changing world, few machines evolved as remarkably as the mini digger. Humble tools designed for specific jobs have transformed into engineering marvels reshaping construction. Tracing mini diggers’ roots to modern form reveals significant progress revolutionizing project approaches. This blog post explores mini diggers’ evolution, construction impact, and the factors behind their versatile, maneuverable, cost-effective nature.

Mini Diggers’ Progression

Origins: Compact digger alternatives emerged in the 1970s for light landscaping and trenching tasks. These diminutive, agile machines marked the beginning.

Hydraulics Innovation: Adopting hydraulic systems was key to mini diggers’ advancement, allowing precise motion control and boosting efficiency and versatility.

Compact Design Evolution: Over time, mini diggers shrank to suit tight spaces and urban areas inaccessible to larger equipment.

Mini diggers have new technology, like GPS tracking, telematics, and robotic features. This tech boosts work speed, safety, and proficiency at construction places.

How Mini Diggers Shake Up Construction

They make tasks quicker and more precise, upping efficiency markedly. Their compact size allows working in tight spaces, reducing need for manual labor and disruption nearby.

Compared to bigger diggers, mini ones cost less upfront and to operate. Their smaller size means less fuel and upkeep costs, attracting contractors and rental firms.

Mini diggers are flexible workhorses, able to dig, trench, grade, and handle materials. Swapping attachments further broadens their range, letting them easily adapt to various jobs.

How Mini Diggers Get So Versatile, Manoeuvrable, And Cost-Effective

They take many attachments – buckets, breakers, augers, grapples – boosting capabilities and versatility. Their manoeuvrable design allows accessing cramped sites where larger equipment can’t go, reducing labor costs.

Rubber tracks: Many mini diggers today have rubber tracks rather than old steel ones. Rubber tracks offer better grip, less damage to the ground, and cause minimal harm to delicate surfaces. This improves steering and usefulness.

More fuel efficient: Newer engine technology has made mini diggers much better at using fuel. Efficient engines cut costs and help the environment.

Easier to move: Mini diggers are small and lightweight, so they’re simple to transport between work sites. This reduces transportation expenses and downtime.

Mini diggers evolved greatly from humble starts to today’s technological wonders, reshaping construction. Their compact size, flexibility, maneuverability, and cost-effectiveness make them crucial tools worldwide for contractors and builders. As technology advances further, we’ll see more innovations to mini excavator design, cementing their essential role in construction even more.

Source: https://www.ozdiggers.com.au/mini-digger-a-journey-from-humble-beginnings-to-technological-marvels/

Source article published by Oz Diggers

Read more about Mini Diggers

Australian Farming Reborn: Compact Diggers Take Centre Stage

Tiny Powerhouses: Mini Diggers Boost Efficiency At Construction Sites

Uncovering Mini Diggers: Compact Powerhouses Transforming Aussie Urban Construction

Diving Deep Into Mini Digger Safety: Essential Advice For Australian Operators

Introducing Australia’s Earth-Friendly Trailblazers: Mini Diggers and Sustainable Excavation

Uncovering Potential: Mini Excavators Shape Australian Landscapes

Picking The Right Tool: Mini Diggers Or Big Excavators For Your Aussie Site