Picking The Right Tool: Mini Diggers Or Big Excavators For Your Aussie Site

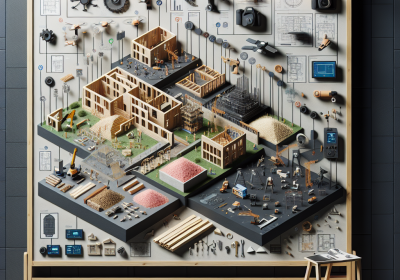

When starting a building or digging job Down Under, choosing gear is key. Mini diggers and huge excavators each have pros, but figuring out which fits best means mulling over a few things. Here, we’ll spell out the good and bad of mini diggers versus larger excavators, eyeing things like cost, moving around, and doing different jobs.

Cash Costs: Are Mini Diggers Cheaper?

Mini Diggers: Go Easy On Your Wallet

Mini diggers, a.k.a. compact excavators, often cost less upfront than bigger rigs. Their small size keeps the starting price down, making them great for budget projects. Also, mini diggers usually burn less fuel, saving even more dough on the job.

Larger Excavators: Shell Out Now, Maybe Save Later

Bigger excavators need deeper pockets upfront, no doubt. But their muscle and speed might wrap up jobs quicker, maybe chopping labor costs and shortening projects. Still, weigh the long-term perks against the steep price tag.

Maneuverability: Navigating Tight Spaces

Mini Diggers: Agile And Nimble

Mini diggers boast exceptional maneuverability. Their compact size grants access to tight areas where big excavators can’t go. This makes them very useful for urban projects or residential areas with little space.

Larger Excavators: Power And Reach

While lacking mini diggers’ agility, bigger excavators have greater power and reach. Perfect for large excavation tasks or heavy materials handling. However, their bulky build limits use in projects with restricted access or delicate surroundings.

Versatility: Adapting To Diverse Project Requirements

Mini Diggers: Multi-Purpose Performers

Mini diggers excel at versatility with the right attachments. From digging trenches and foundations to landscaping and demolition, these compact machines handle diverse tasks. Ideal for small to medium projects requiring various capabilities.

Larger Excavators: Specialized Efficiency

Though less versatile than minis, larger excavators shine in specialized tasks demanding immense power and capacity. Whether earthmoving for major construction or mining operations, their rugged build and high performance ensure efficient operation in demanding environments.

Picking The Proper Gear: Key Factors

Project’s Size And Scope

How big and complex your project is really matters when choosing equipment. For small jobs or tight spots, a mini digger could be just right – flexible and efficient. But for major excavations or heavy-duty tasks, you’ll likely need a full-sized excavator’s brawn.

Site Access And Terrain

Think about how accessible the work site is and what terrain you’ll face. Mini diggers shine when squeezing into cramped areas or handling uneven ground, great for urban or residential projects with limited entry. Larger excavators, though, may struggle there but excel in wide-open spaces with plenty of room to maneuver.

Budget Limitations

Of course, cost plays a role in your choice. Mini diggers provide affordable options for many projects. But bigger excavators, despite higher upfront prices, might pay off better long-term with greater efficiency and output – weigh the potential return against your budget.

These sources offer helpful info on construction and excavation, data on equipment specs, market trends, and industry best practices.

When selecting equipment, look beyond just the current project’s needs. Consider long-term factors too. Carefully weigh mini diggers’ and excavators’ pros and cons for cost, maneuverability, and versatility. Make a balanced choice maximizing productivity and efficiency while respecting budget limits.

Additionally, it’s crucial to think about the environmental impact of your equipment choice. While both mini diggers and larger excavators have their own footprint, choosing more fuel-efficient models can minimize emissions and reduce environmental harm. Many manufacturers now offer eco-friendly options with advanced engine technologies and emission control systems. These provide a greener alternative for construction and excavation projects.

Moreover, don’t overlook the importance of operator skill and training when selecting equipment. The most advanced machinery can only perform as well as the operator’s proficiency allows. Ensure your team receives adequate training and certification to operate the chosen equipment safely and efficiently. This minimizes the risk of accidents or downtime.

Additionally, consider conducting a thorough site assessment to identify any potential obstacles or constraints. These may impact equipment maneuverability and accessibility. Understanding the unique characteristics of your project site allows for a more informed decision on the most appropriate equipment.

Furthermore, seeking advice from industry professionals and equipment suppliers can provide invaluable guidance. This guidance is tailored to your specific project requirements. Consulting with experienced contractors, engineers, or equipment rental companies can offer insights. These insights determine which equipment is best suited to effectively tackle your project’s challenges.

As you look at equipment, don’t forget about maintenance. Regular servicing keeps things working well and prevents delays. Consider spare parts availability and tech support. Quick repairs can really affect timelines and costs.

Warranty and after-sales support are key too. Buying from respected brands with solid warranties and good customer service gives you peace of mind. Unexpected issues won’t derail you as easily.

Stay updated on industry changes and new excavation/construction tech. Things like automation, GPS tracking, and telematics are transforming projects. Better efficiency, safety, and output are possible by using the latest innovations.

Compliance and rules around operating equipment in Australia matter. Learn relevant safety regulations, licensing needs, and environmental rules. Avoid fines/penalties by following the law.

Think about impacts on local communities too. Noise, dust, and infrastructure disruptions can affect approvals and community relations. Choose low-impact equipment and address concerns to keep good relations.

Additionally, team up with others in the industry for chances to cooperate and partner. Networking with other contractors, suppliers, and industry groups can give valuable insights, resources, and support. Joint approaches like sharing equipment or joint ventures can optimize resource use and cut costs.

Lastly, welcome innovation and continuous improvement in equipment choice and project management practices. Rapidly changing technology in construction and excavation offers new tools and solutions for better efficiency, safety, and sustainability. Stay open to adopting fresh technologies, methods, and best practices to stay ahead and succeed.

In closing, deciding between mini diggers and larger excavators for Australian construction or excavation needs careful thought of various factors. Mini diggers are cost-effective, maneuverable, and versatile, while larger excavators excel at power, reach, and efficiency.

Assess your project’s needs, considering budget limits, site conditions, and regulatory compliance, and stay informed on trends and innovations. This informs the right choice to maximize success.

Ultimately, whether a mini digger or larger excavator, ensure it aligns with goals, budgets, and environmental and safety standards. Careful planning, strategic decision-making, and industry expert/resource support ensure efficient, effective equipment selection and project execution.

Source article published by Oz Diggers

Read more about Mini Diggers

Australian Farming Reborn: Compact Diggers Take Centre Stage

Tiny Powerhouses: Mini Diggers Boost Efficiency At Construction Sites

Uncovering Mini Diggers: Compact Powerhouses Transforming Aussie Urban Construction

Diving Deep Into Mini Digger Safety: Essential Advice For Australian Operators

Small Digging Machines: From Modest Beginnings to Astounding Tech

Introducing Australia’s Earth-Friendly Trailblazers: Mini Diggers and Sustainable Excavation

Uncovering Potential: Mini Excavators Shape Australian Landscapes